Plastic Injection Moulding Electronics Parts Mould

- Jinen/Jinjiekun

- Xiamen City, China

- 30 days

- 50 Sets Per Month

1. We have more than 50 plastic injection mold machines、variety of precision mold produce equipment and spray printing equipment.

2. Our workshop area is about 7500 square meters;

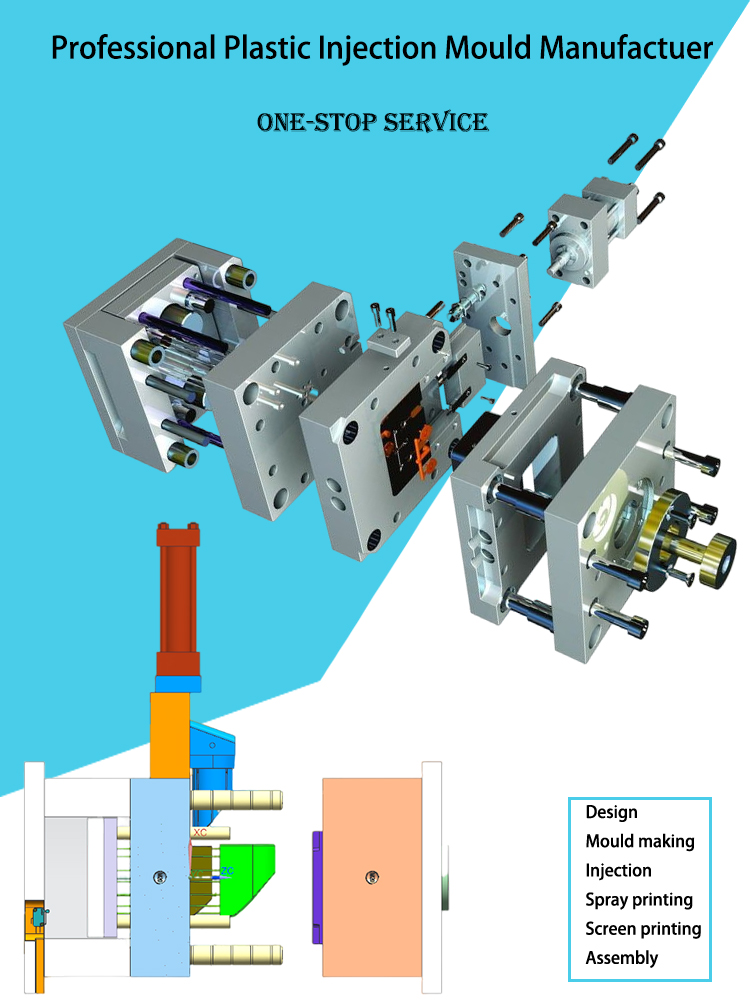

3. We can provide ONE-STOP SERVICE for plastic product customizing works. We provide mold design, precision plastic mold making, custom best quality plastic injection molding, Assembly Work, Pad Printing, Silk Screen Print, Paint, Ultrasonic Welding and Packaging Services.

4. 3D Drawing service from plastic to plastic injection moulding tool design

5. 2 special after sales team to help you solve any problem for plastic injection mold tooling and parts.

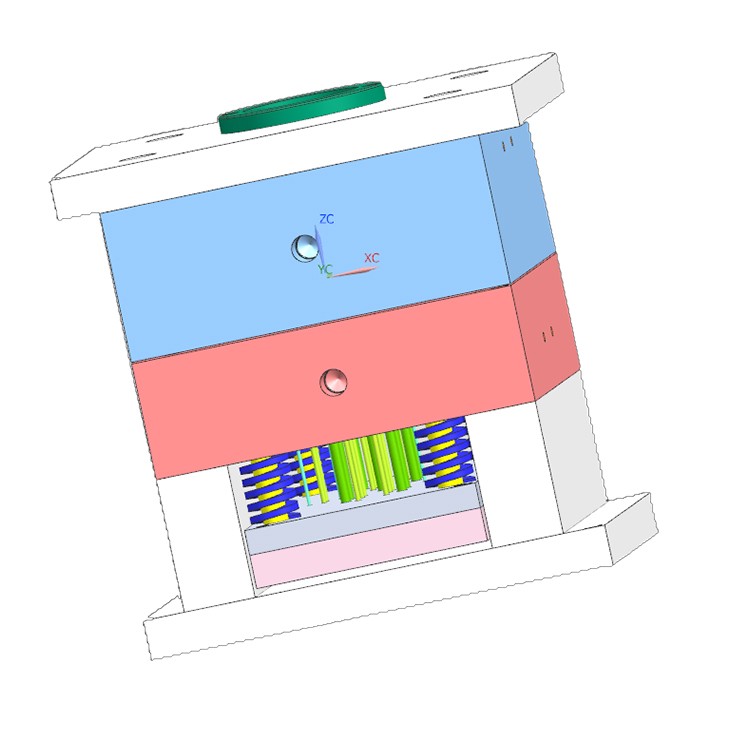

Plastic Injection Moulding Electronics Parts Mould

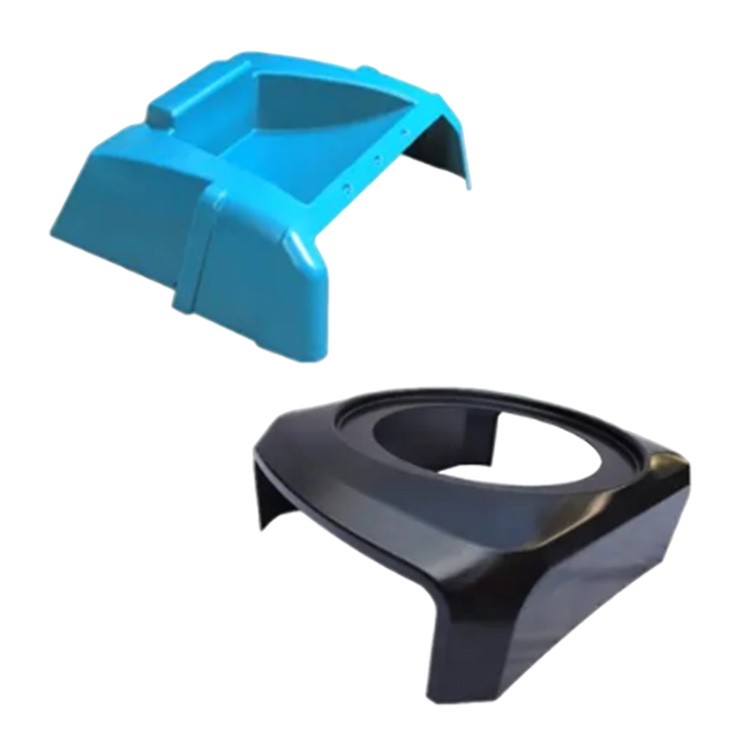

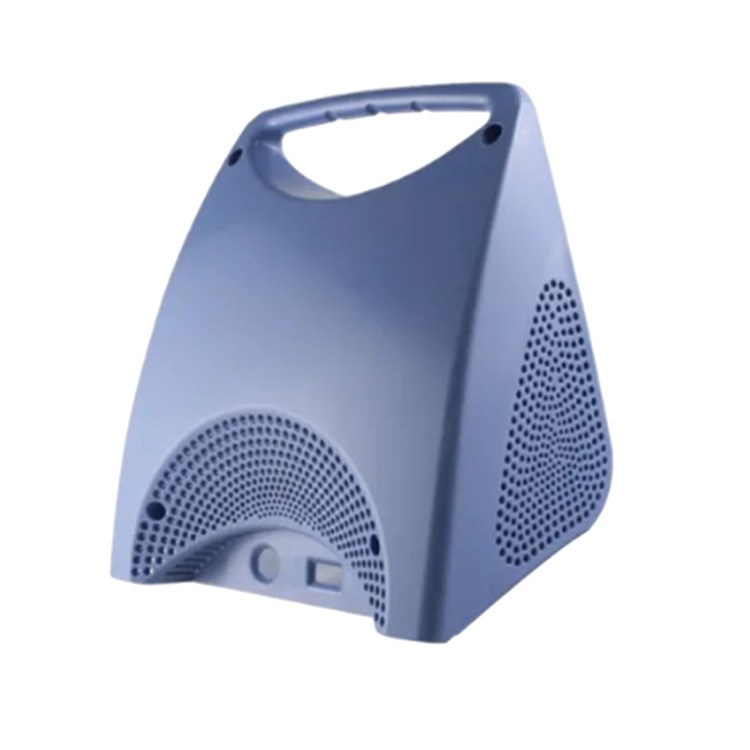

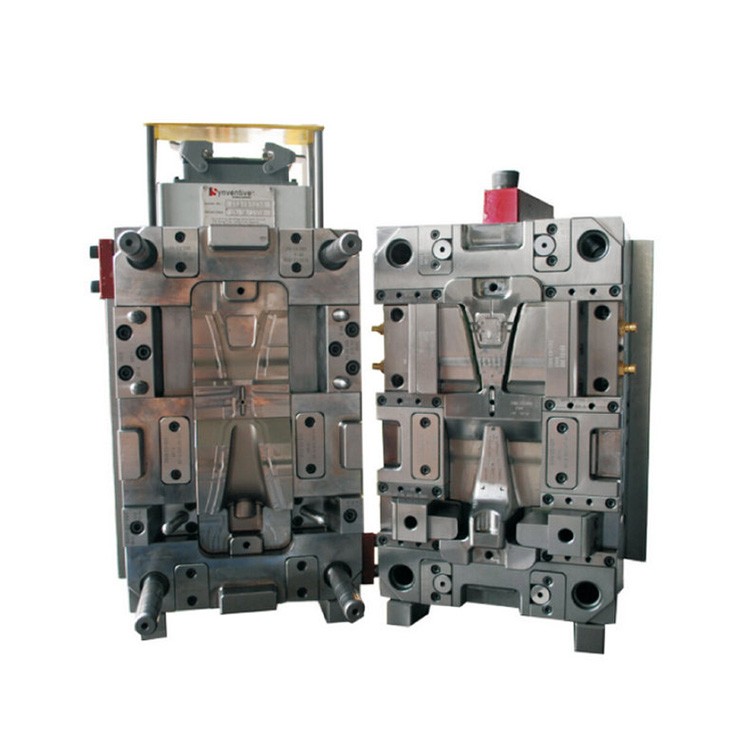

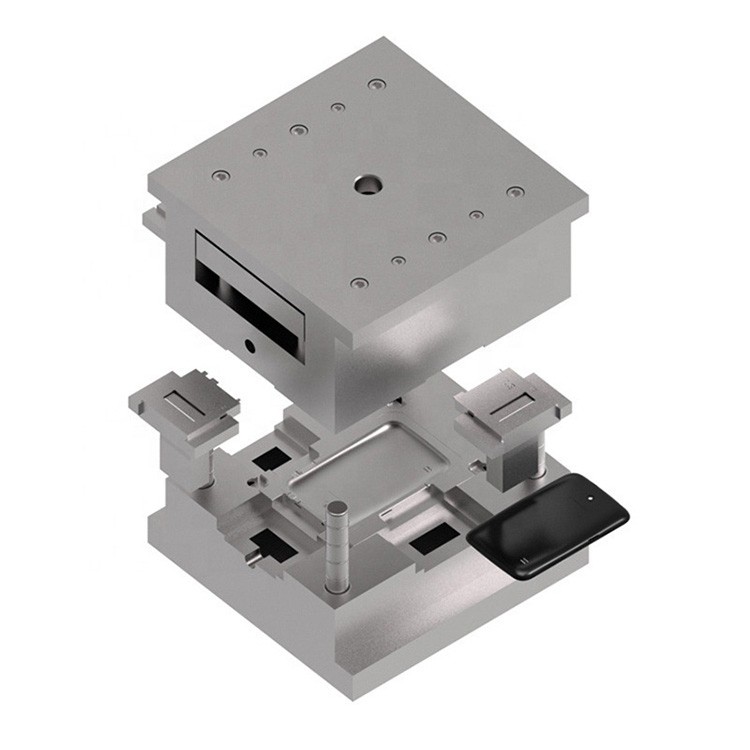

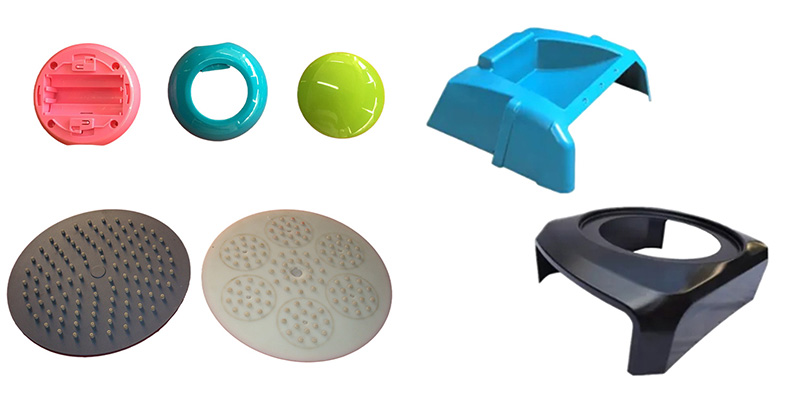

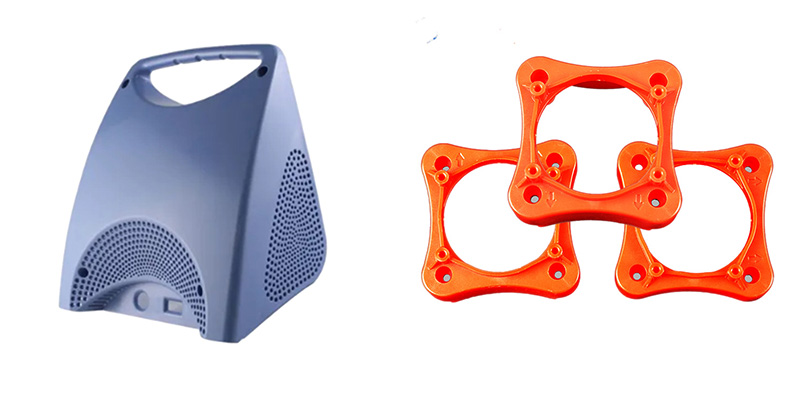

Plastic Electronics Mould and Products Show:

Plastic Electronics Mould Information:

| Product type: | Plastic Injection Moulding Electronics Parts Mould |

| Mould material: | P20,NAK80, S136, 718H, etc.(Hardness 35~55HRC) |

| Ejection system: | Motor/hydraulic cylinder/stripping plate/angle pin,etc |

| Design software: | UG, PROE, CAD, CAXA ect. |

| Surface treatment: | Polish,texture,sandblasting,chrome |

| Mould life: | 300,000~ 1,000,000 shots |

| Delivery time: | 25~30 days for delivey T1 samples, depands on product instruction. |

Our Services:

Packing and Delivery:

FAQ:

Q1:How can I get the sample to check your quality?

A1:After price confirmation, you can require for samples to check our product's quality.

A2:We usually quote within 24 hours after we get the enough infomation of the products.

Q3: What is the quality control of your company?

A3: Our company has the system certification of ISO9001. We have special product measurement room, and have very professional testing & measuring equipment. We do raw material incoming inspection, in-process product quality control and outgoing goods quality control.