Plastic Cover Mould Injection Plastic Molding

- Jinen/Jinjiekun

- Xiamen City, China

- 30 days

- 50 Sets Per Month

1. 7500 square meters factory mainly provides CNC machining service and plastic injection service.

2. ISO certificated,supports third-party verification.

3. Fast deliver conventional products, the lead time depends on the mold's size and complexity. Normally, the lead time is 25_45 days. If the Plastic Mouldings are very simple and not big size, we can work out within 15 days.

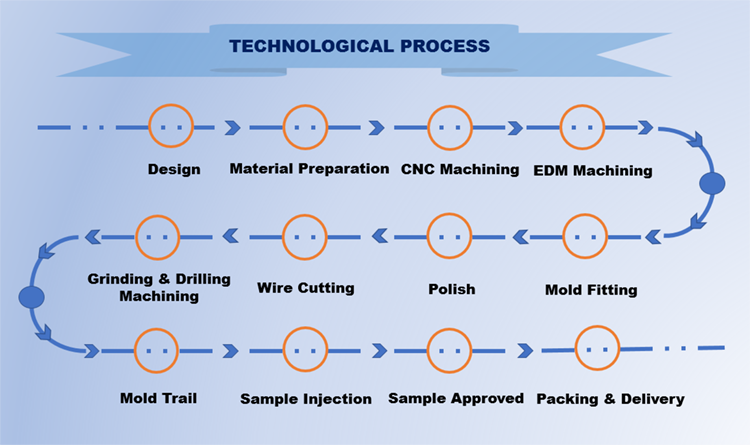

4. Engineering service provided, with more than 10 engineers, for mold design, programming, project managers, we are using CAD/CAE/CAM software to do the design, analysis & programming, to guarantee the satisfaction of customers.

Plastic Cover Mould Injection Plastic Molding

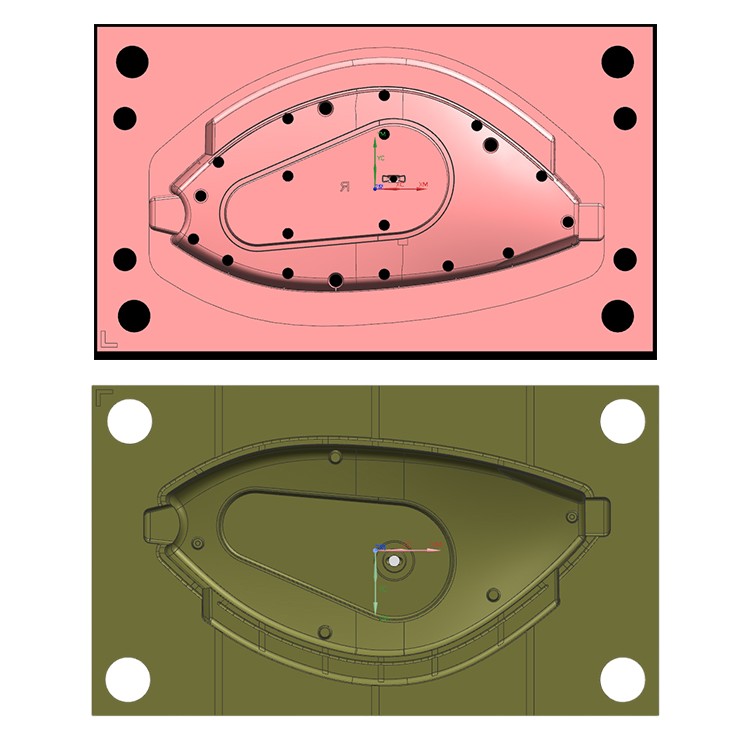

Plastic Injection Mould Specification:

Mould material | 45#, 50#, P20, H13, 718, 2738, NAK80, S136, SKD61 etc. (Hardness 35~55HRC) |

Mould base | Standard mould base, LKM, HASCO etc. |

Cavity | Single/multi |

Runner | Hot/cold |

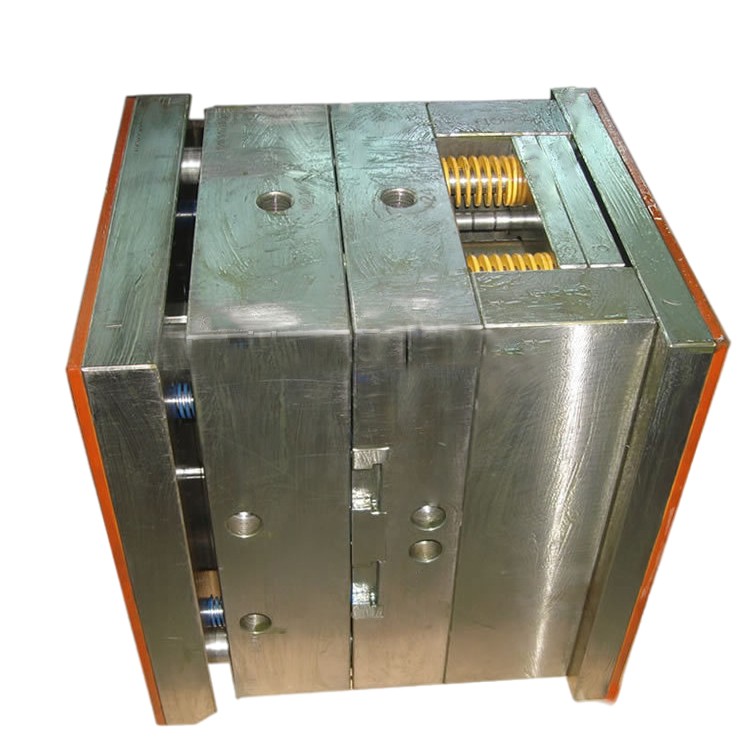

Ejection system | Motor/hydraulic cylinder/stripping plate/angle pin, etc. |

Cooling system | In core baffle and in cavity plate chain drilling type cooling |

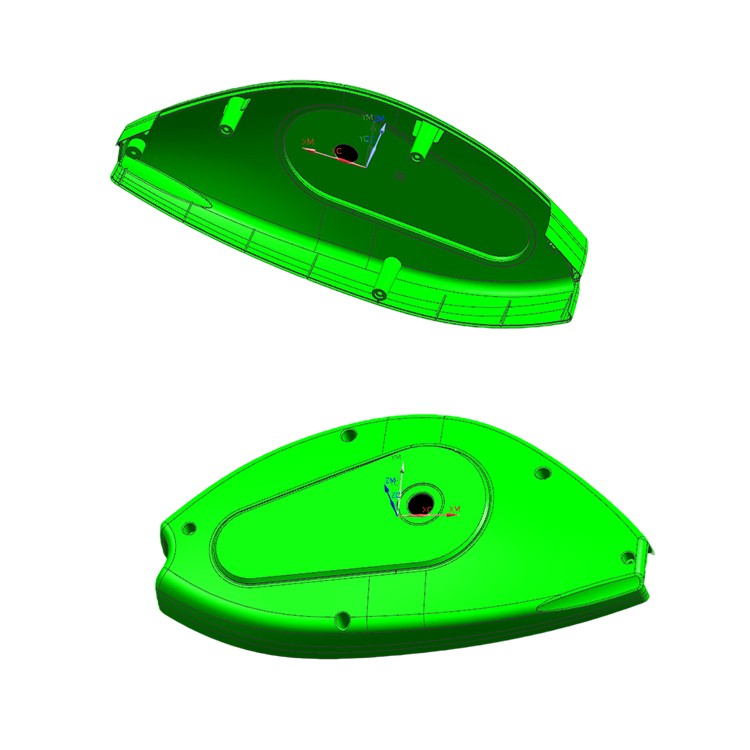

Design software | UG, PROE, CAD, CAXA etc. |

Plastic material | ABS, GPPS, HIPS, AS, MS, PMMA, PC, PA6, PA66, PA+GF, PVC, PP, PE, TPE, TPU, TPR, LCP, PBT, PETG, PC/ABS, POM, PPS, PC, PPE, PPO, etc. |

Surface treatment | Polish, texture, sand blasting, chrome plating |

Mould life | 300,000-1,000,000 shots |

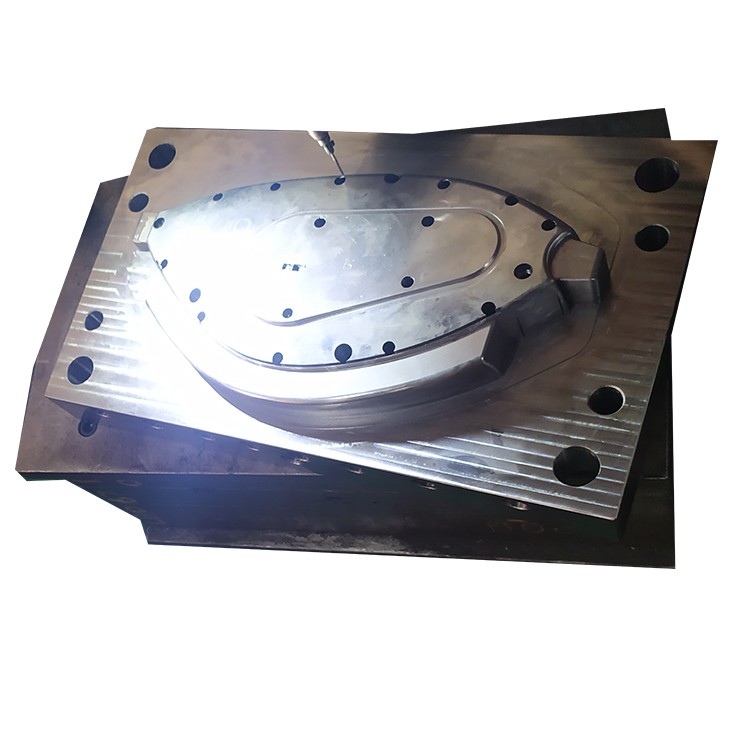

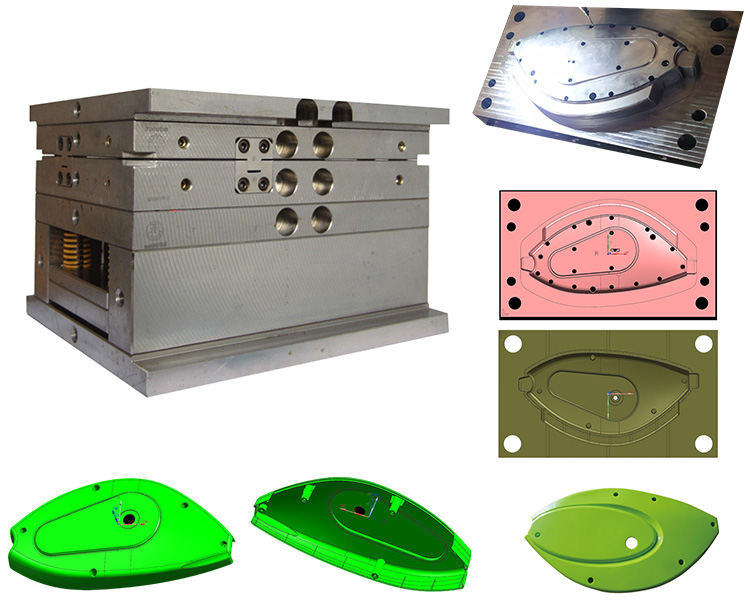

Plastic Injection Mould and Products Show:

Plastic Injection Mould Feature and Application:

1. Efficiency production and automotive operation;

2. Shape can be from simple to complex, the size can be from large to small and the product size is accurate;

3. It is used in the forming and processing fields of mass production and products with complex shapes.

The moulds we make involves house appliance, fitness equipment, electronics, industrial, auto parts, bathroom, medical, over molding and so on.

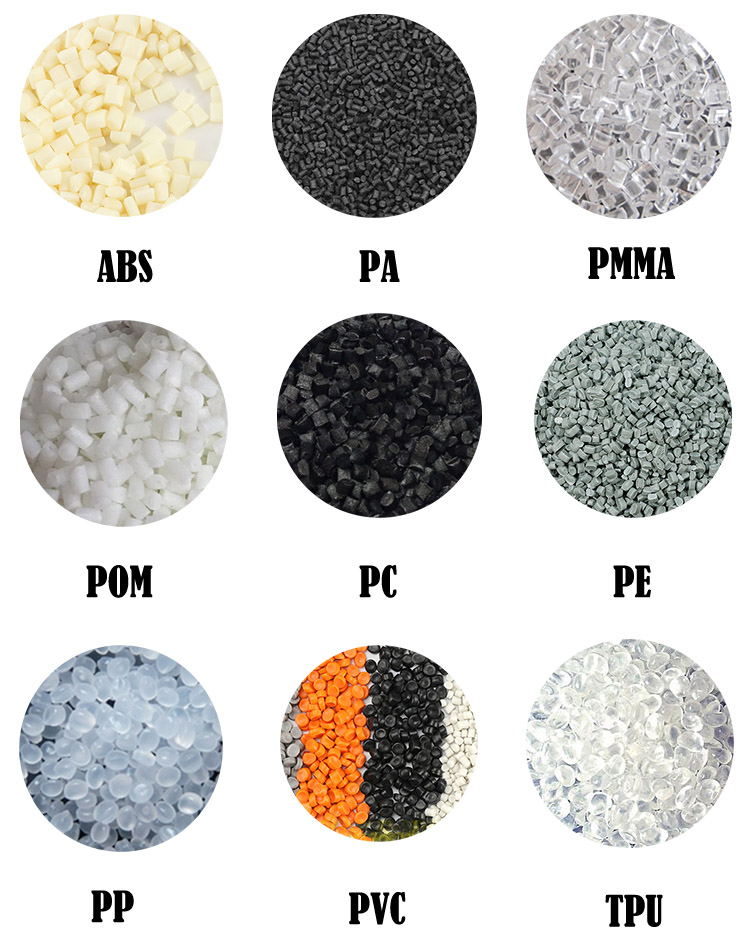

Plastic Raw Material:

The common material of the plastic parts as the following:

ABS, GPPS, HIPS, AS, MS, PMMA, PC, PA6, PA66, PA+GF, PVC, PP, PE, TPE, TPU, TPR, LCP, PBT, PETG, PC/ABS, POM, PPS, PC, PPE, PPO, etc.

Plastic Injection Mould Manufacturer Information:

We were established in 2001 (Its formerly is Xiamen King trade Co., Ltd.). We are a manufacturer of Plastic injection mould and plastic products express in plastic parts of sport equipment. Now we are one of the important manufacturers in sport equipment industry. We also produce and sales plastic households products and plastic electronic products.

We are located in Xinglin development, Jimei district zone, Xiamen City. We have 20 plastic injection mold machines、variety of precision mold produce equipment and spray printing equipment. Our workshop area is about 7500 square meters and we have precision production equipment which reach the international advanced level and the experienced technician. Now our production value can reach 1.4 Billion RMB. “Quality first, continuous improvement, respect individual, team spirit” is our top management objective. We will make “build quality brand, service the needs of customers” as our guiding ideology.

Our Plastic Injection Mould Case Show:

Payment and Shipping:

We accept many kinds of the payment, the details as the following:

1. For the samples, we can accept PayPal, West Union and Bank Transfer as the payment, and will ship the samples by air express, such as the DHL, UPS and FEDEX.

2. For the bulk order, we can suggest the bank transfer as the payment method with the 30% deposit, we will ship out the goods according to the choice from the customers for shipping.

3. We can ensure the shipping is fast and efficient.

FAQ about Plastic Mould Manufacturing:

Q1: What kind of molds do you make? Plastic injection mold, Die casting mold or something else?

A1: We are mainly making plastic mold injection. Sometimes we also make Die casting mold and stamping molds according to our customer’s requirements.

Q2: What types of files do you accept (drawings)?

A2: With our CAD systems we can accept following files: STP, IGS, DXF, DWG, Cad Key PPT, STL, X_T, CATIA, UG files, etc.

Q3: What kind of steel do you use for plastic mouldings?

A3: We can use any type of steel appointed by customer or popular in the market. Such as P20, 718, 8407, NAK80, H13, S136, DIN 1.2738, DIN 1.2344, etc.

Q4: Can you make the texture / text / heat treatment /nitriding for the plastic injection mold?

A4: Yes, as plastic mold factory, we have long term cooperated subsidiary factories that do those processes. They are professional and well reputed in our local market.

Q5: Do you make spare parts for your customer?

A5: Yes, we will provide spare parts for the mold if needed or required by client.

Q6: How do you pack the china plastic moulds?

A6: We pack the plastic moulds with wooden box.