Households Plastic Injection Stool Mould

- Jinen/Jinjiekun

- Xiamen City, China

- 30 days

- 50 Sets Per Month

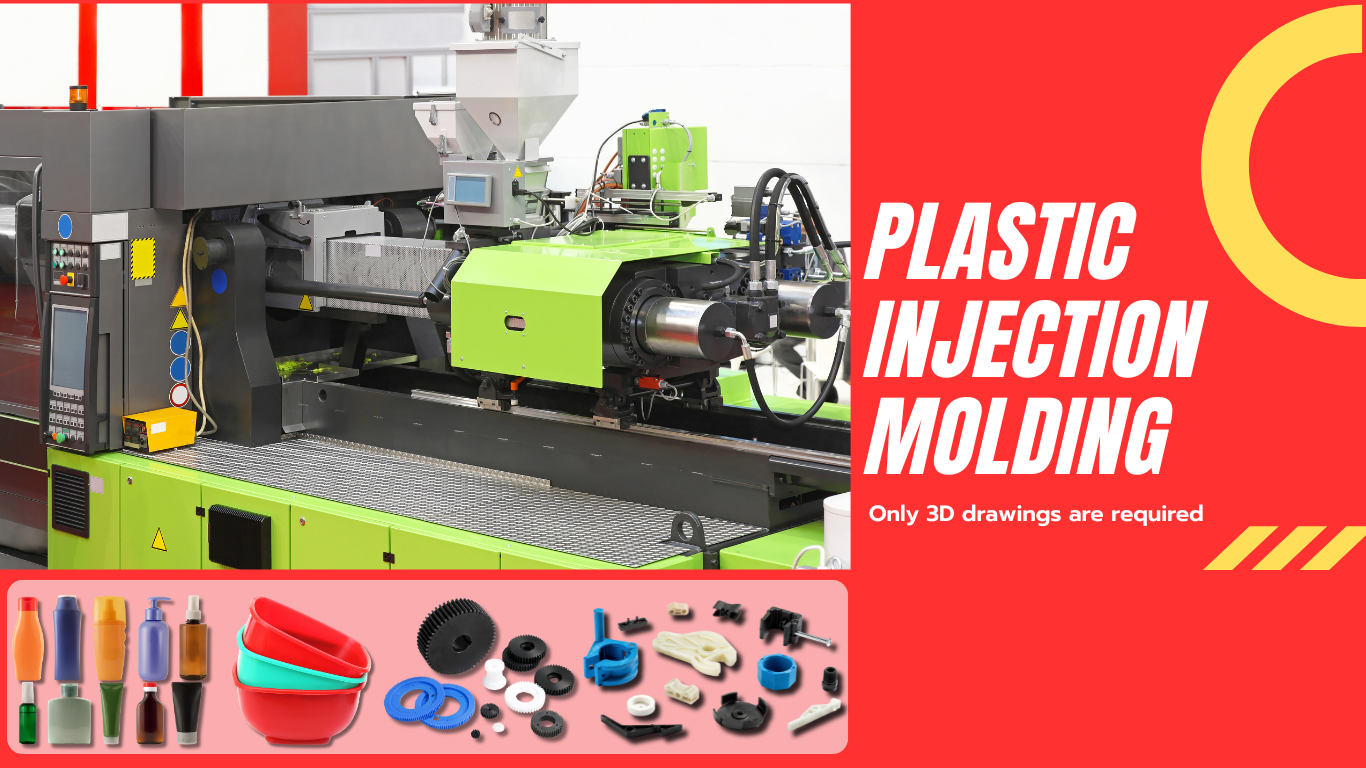

1. Deliver a wide variety of injection molded, CNC machined, and 3D Printed parts in under fifteen (15) business days;

2. OEM&ODM Service, with more than 10 engineers for plastic product and plastic injection mold design, programming, project managers. we are using CAD/CAE/CAM software to do the design;

3. Fast delivery, generally, it takes 40 days ( 30 days do mold and 10 days do mass production);

4. One-stop service from mold design, mold making, injection production, screen printing, spray paint, assembly, packing to shipping.

Households Plastic Injection Stool Mould Specification:

| Mould material | P20/718/738/NAK80/S136/2738/2316/H13 etc. | Mould base | DME, SD, LKM, HASCO etc. |

| Mold Accuracy | +/-0.001mm | Mold Life | Hot/Cold |

| Runner System | Hot runner/Cold runner or combined | Mould Equipement | High speed CNC, EDM, Wire cutting, Grinding, Laser Marking, Drilling, Spotting machine |

| Molding Facility | 60 to 950ton plastic injection machines | Package | Standard exported Wooden box packed, Fumigation process(upon required) |

| Surface treatment | Texture(MT standard), High gloss polishing | Product Name | Households Plastic Injection Stool Mould |

The application range of plastic home molds is very wide, covering the production of daily necessities to home appliances.

Plastic home molds are mainly used to produce various daily necessities and home appliances.

These molds can produce plastic shells of home appliances including but not limited to children's toys, game consoles, televisions, washing machines, refrigerators, etc.

These products are widely used in people's daily lives, providing great convenience and comfort for people's lives.

Specific to the type of molds, plastic home molds include injection molds, extrusion molds, blow molding molds, compression molds, blister molds, and high-foam polystyrene molding molds.

These molds each have specific application areas:

Injection molds: suitable for the production of thermoplastic plastic parts, such as various daily necessities, home appliances, and transportation parts.

Extrusion molds: suitable for continuous production, high efficiency, used to produce plastic rods, plastic plates, water pipes, etc.

Blow molding molds: used to mold hollow plastic container products, such as beverage bottles, milk bottles, oil drums, etc.

Compression mold: Mainly used for molding thermosetting plastics, such as packaging electrical components.

Blister mold: A molding method using vacuum or compressed air, used for packaging products such as daily necessities, food, and toys.

Highly expanded polystyrene molding mold: Used to mold foam plastic packaging materials of various desired shapes, suitable for packaging products in the consumer industrial sector.

Plastic Raw Material:The common material of the plastic parts as the following:

ABS, GPPS, HIPS, AS, MS, PMMA, PC, PA6, PA66, PA+GF, PVC, PP, PE, TPE, TPU, TPR, LCP, PBT, PETG, PC/ABS, POM, PPS, PC, PPE, PPO, etc.

Others Plastic Households Mould