Fitness Equipment Spare Parts Plastic Injection Mold

- Jinen/Jinjiekun

- Xiamen City, China

- 30 days

- 50 Sets Per Month

1. Start from part design analysis;

2. Mold design drawing and DFM report available so you can see how is the mold going to be before mold making;

3. If product is complex, moldflow report will be present as well;

4. In house mold making shop ensure you mold quality under well control;

5. Normally it takes 20-40 days to make mold, precise time depends on part design;

6. We can provide mold design, mold tooling, injection production, screen printing, spray paint and assembly one-stop service;

7. With more than 50 injection molding machines, plastic extruding machines, as well as various accurate mould opening equipment, lacquer spraying and printing equipment;

8. Our machines produce the unit parts from 1 gram to 6000 grams weight. Our machines can produce the maximum size of unit plastic part: 1.5*1.5*1.5 meters.

Fitness Equipment Spare Parts Plastic Injection Mold

Plastic Fitness Equipment Mould Description:

Product Name | Fitness Equipment Spare Parts Plastic Injection Mold |

Mold Material | P20/718/738/NAK80/S136/2738/2316/H13 etc. |

Mold Accuracy | +/-0.001mm |

Mold Life | 50K-1.5Million Shots |

Hot/ Cold Runner | HUSKY, INCOE, YDDO, HASCO, DME, MoldMaster, Masterflow, Mastip, Taiwan made brand...etc |

Mold Equipement | High speed CNC, EDM, Wire cutting, Grinding, Laser Marking, Drilling, Spotting machine |

Molding Facility | 60 TO 950ton Plastic injection machines |

Mould Base | DME, SD, LKM, HASCO and so on |

Surface Treatmetn | Mirror Polishing, Texture MT(series), laser engraving, PVD coating, Nitriding |

Design & Program Softwares | CAD, CAM, CAE, Pro-E, UG, Soild works, Moldflow, CATIA....etc |

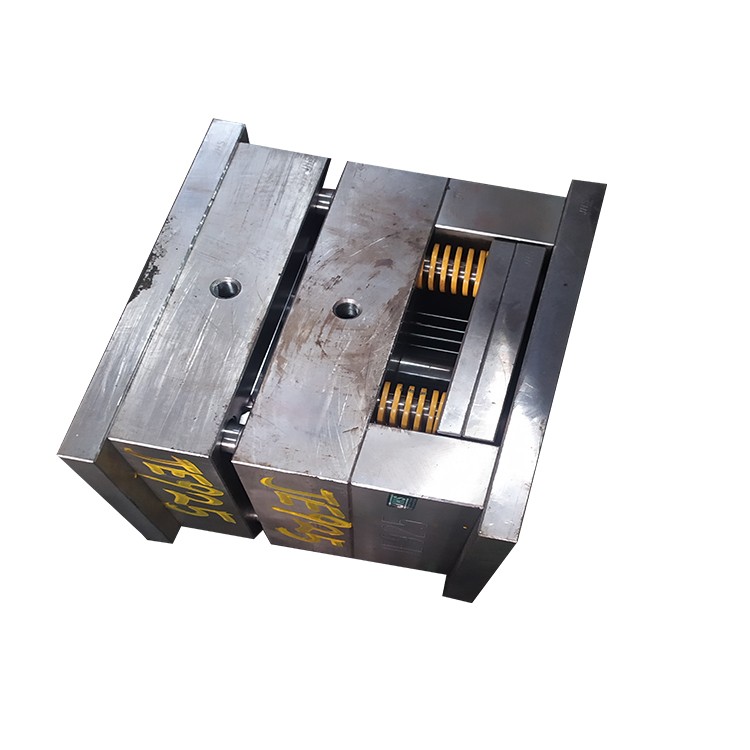

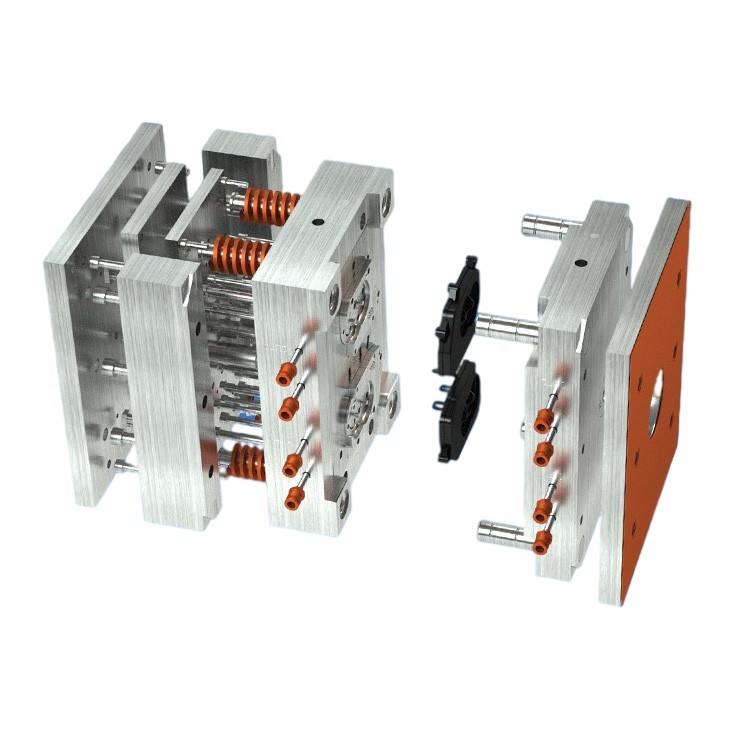

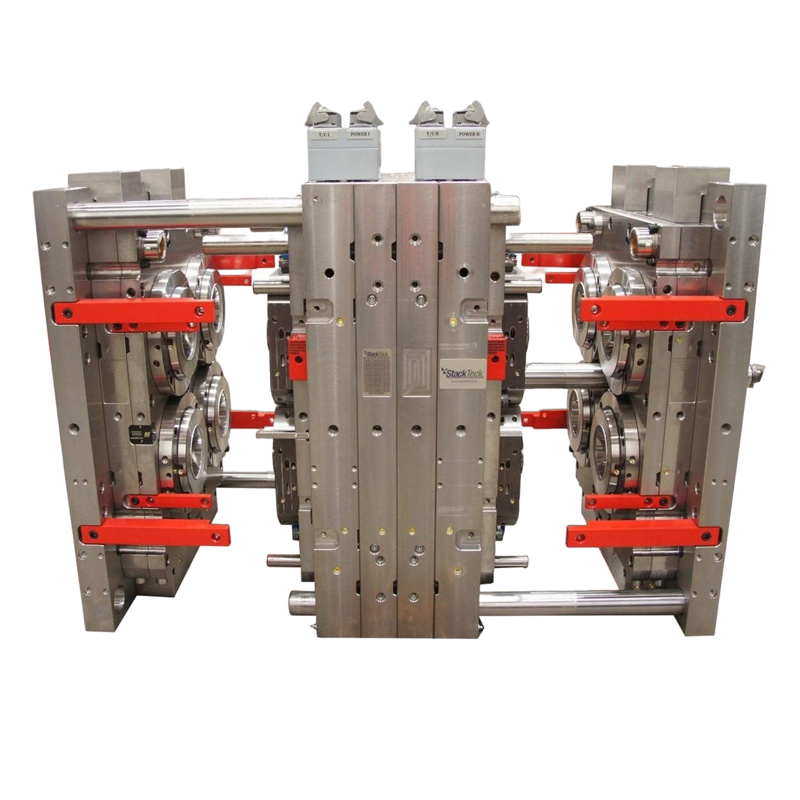

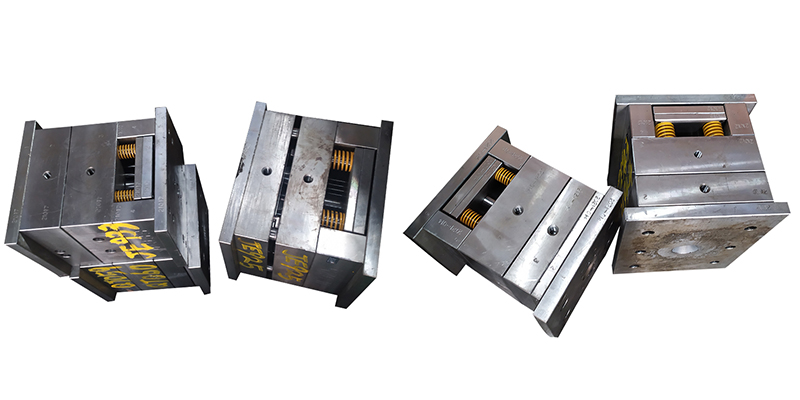

Plastic Fitness Equipment Mould and Products Show:

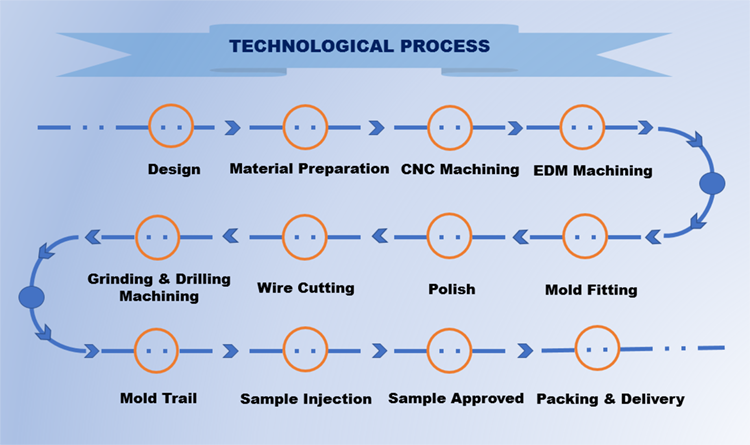

Plastic Fitness Equipment Mould Processing Flow:

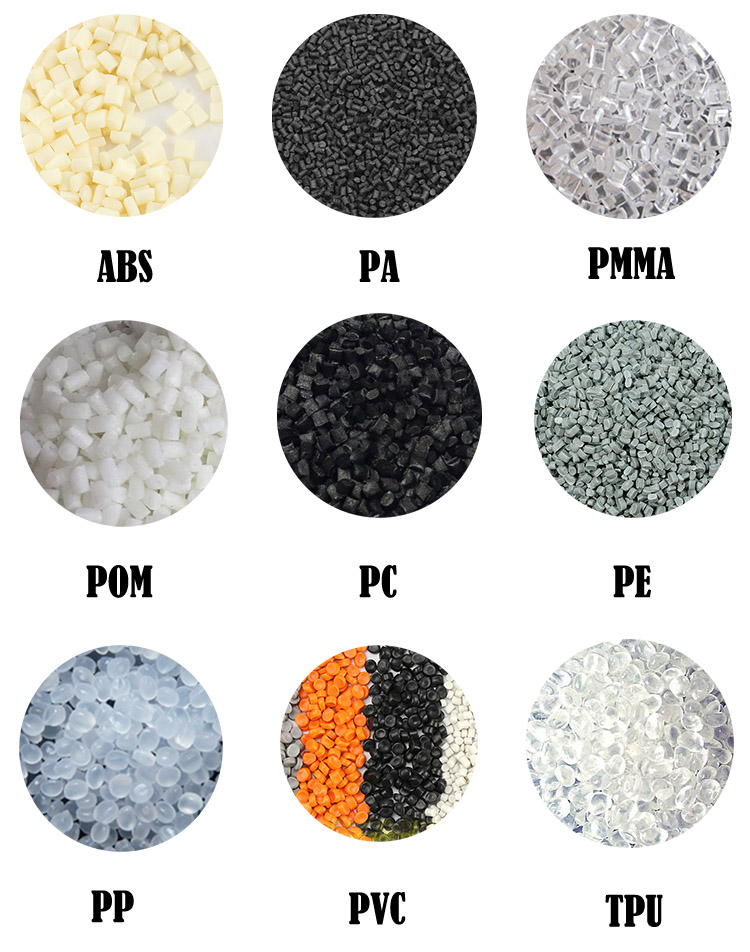

Plastic Raw Material:

The common material of the plastic parts as the following:

ABS, GPPS, HIPS, AS, MS, PMMA, PC, PA6, PA66, PA+GF, PVC, PP, PE, TPE, TPU, TPR, LCP, PBT, PETG, PC/ABS, POM, PPS, PC, PPE, PPO, etc.

Certificate:

Exhibition:

Every year we attend China Sport exhibition in Shanghai.

FAQ:

Q1: What kind of molds do you make? Plastic injection mold, Die casting mold or something else?

A1: We are mainly making plastic mold injection. Sometimes we also make Die casting mold and stamping molds according to our customer’s requirements.

Q2: What types of files do you accept (drawings)?

A2: With our CAD systems we can accept following files: STP, IGS, DXF, DWG, Cad Key PPT, STL, X_T, CATIA, UG files, etc.

Q3: What kind of steel do you use for plastic mouldings?

A3: We can use any type of steel appointed by customer or popular in the market. Such as P20, 718, 8407, NAK80, H13, S136, DIN 1.2738, DIN 1.2344, etc.

Q4: Can you provide the steel certificate and heat-treatment certificate?

A4: Yes, we can provide steel certificate or hardness certificate to prove.

Q5: Can you make the texture / text / heat treatment /nitriding for the plastic injection mold?

A5: Yes, as plastic mold factory, we have long term cooperated subsidiary factories that do those processes. They are professional and well reputed in our local market.

Q6: How long is the lead-time for a plastic injection mold?

A6: It all depends on the mold's size and complexity. Normally, the lead time is 25_45 days. If the Plastic Mouldings are very simple and not big size, we can work out within 15 days.