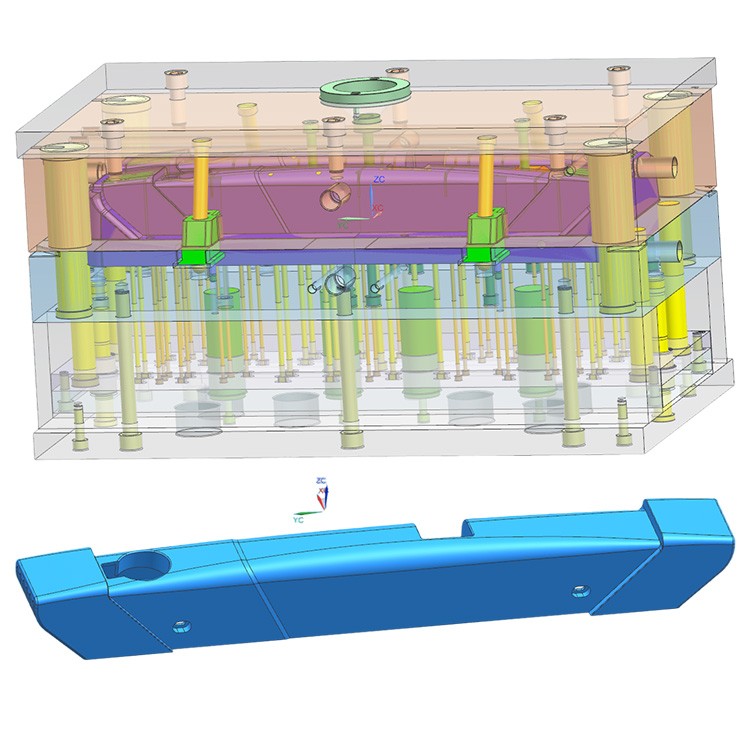

Plastic Injection Mould

Injection molds are widely used in consumer electronics, auto parts, toys, daily necessities, medical devices and other industries, providing efficient and high-quality plastic product production solutions for these industries. Through continuous technological innovation and process improvement, KCN plastic molding is gradually developing towards intelligent and automated injection molds, providing strong support for the development of modern manufacturing.

-

Plastic Injection Moulding Industrial Mould

1.We have more than 50 plastic injection mold machines、variety of precision mold produce equipment and spray printing equipment.

Email Details

2.We can provide ONE-STOP SERVICE for plastic product customizing works. We provide mold design, precision plastic mold making, custom best quality plastic injection molding, Assembly Work, Pad Printing, Silk Screen Print, Paint, Ultrasonic Welding and Packaging Services.

3. 2 special after sales team to help you solve any problem for plastic injection mold tooling and parts.

4. We are ready to sign a contract with you in case you need to ensure our quality OR delivery date of our plastic moulding tooling and plastic parts.

5. We have professional plastic injection mold tooling designer and plastic part producing line.

6. Plastic Injection Mould OEM & ODM Services -

Walking Machine Molding Plastic Injection Mould

1. Have experience for mould;

Email Details

2. 3D Drawing service from plastic to plastic injection moulding tool design;

3. 2 special after sales team to help you solve any problem for plastic injection mold tooling and parts;

4. We are ready to sign a contract with you in case you need to ensure our quality OR delivery date of our plastic moulding tooling and plastic parts;

5. We have professional plastic injection mold tooling designer and plastic part producing line;

6. Plastic Injection Mould OEM & ODM Services;

7. ISO 9001, ISO 14001 Certified for all of our plastic injection tooling and plastic mould part, injection mould and our factory. -

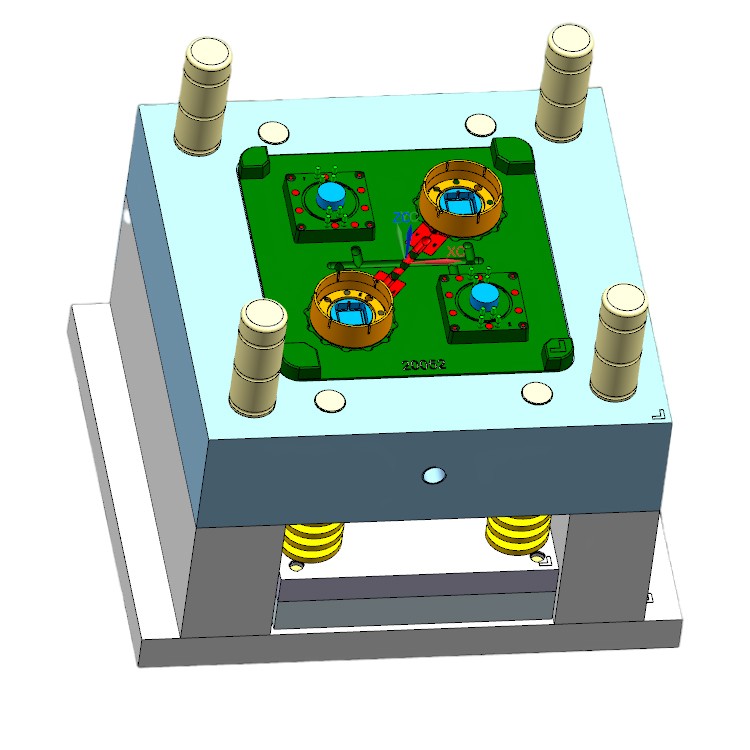

Plastic Mould Injection Molding For Exercise Bike Parts

1. One-stop Service:

Email Details

Support plastic injection mold design and making service, plastic injection service, assembly work service, pad printing service, silk screen print service, paint service, ultrasonic welding service and packaging services;

2. Rich Experience:

more than 15years experience for plastic injection mould and plastic injection and developing capability;

High Quality, Competitive Price and Fast Delivery Time

3. Advance Equipment:

Imported sophisticated production and testing equipment with high stability. -

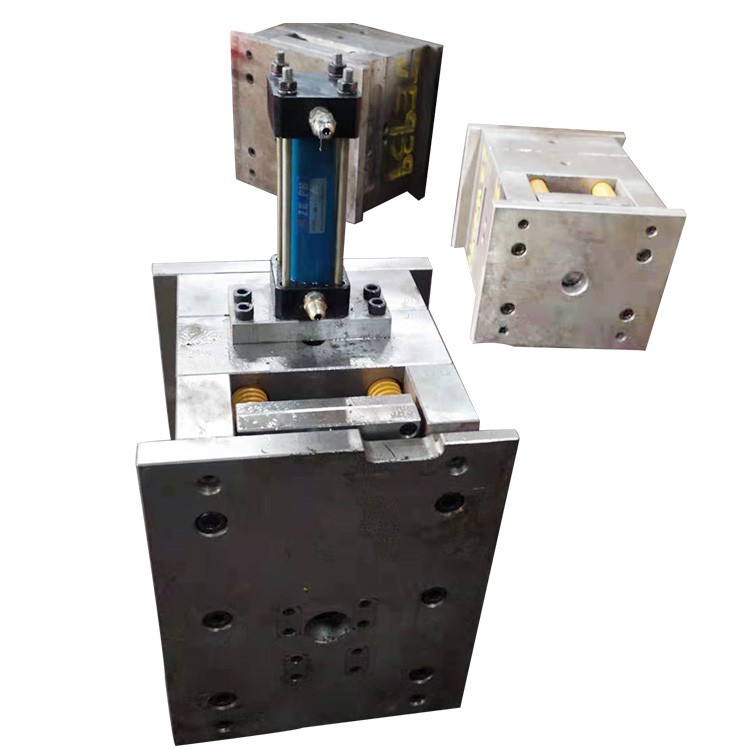

Custom Injection Moulding Plastic Mould

1. Design Service:

Email Details

With more than 10 engineers, for mold design, programming, project managers, we are using CAD/CAE/CAM software to do the design, analysis & programming, to guarantee the satisfaction of customers.

2. Guaranteed delivery:

(1) Have more than 50 plastic injection mold machines、variety of precision mold produce equipment and spray printing equipment.

(2) Our workshop area is about 7500 square meters;

(3) Provide ONE-STOP SERVICE for plastic product customizing works. We provide mold design, precision plastic mold making, custom best quality plastic injection molding, Assembly Work, Pad Printing, Silk Screen Print, Paint, Ultrasonic Welding and Packaging Services.

3. Strict quality management system:

(1) Material inspection--Check the material surface and roughly dimension.

(2) Production first inspection--To ensure the critical dimension in mass production.

(3) Sampling inspection--Check the quality before sending to the warehouse.

(4) Pre-shipment inspection--100% inspected by QC assistants before shipment. -

Injection Molding Precision Injection Plastic Mould

1. High quality and factory price for plastic injection mould service;

Email Details

2. Plastic injection mould design and making service and plastic injection service for over 30 countries; Provide high-volume injection molding solutions;

3. One-stop service from plastic injection mould making to plastic injection and assembly;

4. Collaboration during the mold design process between our customers, management, and our employees to implement the best possible concept;

5. Our unique capacity to create solutions that replace expensive, fabricated steel products. -

Plastic Injection Parts Mold For Bathroom Shower

1. We have our own tooling shop, equipped with advanced machines for plastic injection mould and the plastic injection products.

Email Details

2. We also have their own injection shop, to run the mold test & mass production for customers.

3. We have more than 15years experience for plastic injection mould and plastic injection.

4. We have precision production equipment which reach the international advanced level and the experienced technician.

5. ISO 9001 Certified for all of our plastic injection mould and plastic injection products and our factory; -

OEM Or ODM Injection Parts Injection Plastic Mould

1. Manufacturing experience for more than 15 years and exporting experience for nearly 8 years. ISO 9001 approved

Email Details

2. Products are supplied to over 20 countries.

3. One-stop service for plastic injection products and plastic injection mold making.

4. In-house mold design and building capabilities.

5. No reclaimed material used to ensure high quality.

6. Keep secret to your idea and your design.

7. Professional design team, mold maker engineer. OEM/ODM service.

8. Professional QC and R&D teams to assure high quality. -

Bathroom Parts Plastic Injection Toilet Seat Cover Mold

1. One-stop Service: Support plastic injection mold design and making service, plastic injection service, assembly work service, pad printing service, silk screen print service, paint service, ultrasonic welding service and packaging services;

Email Details

2. Rich Experience: more than 15years experience for plastic injection mould and plastic injection and developing capability;

3. Advance Equipment: Imported sophisticated production and testing equipment with high stability.

4. Fast Quote: Based on 2D or 3D drawing, your sample, even your idea;

5. Tooling Maker: Injection mold, stamping die & die casting as well;

6. After Service:For your smoothly running machine or product use. -

Custom Mold Injection Plastic Mold

Advance Pre-sale service

Email Details

1. Your drawing will be checked carefully or do the design for you by our professional and experienced engineer team;

2. Most of the materials or colors as your requirement.

3. Good Quality, Factory Price ,Quick Response and Reliable Service will offer you.

Advance after you choose:

1. Design the mold drawing and provide DFM report.

2. Update the videos and pictures of each process of your order to check the quality.

3. Offer free samples for your check and confirm.

Advance after-sale service

1. We are very glad that customers give us some suggestions for price and products.

2. If you have any questions, please feel free to contact us by E-mail or Telephone.