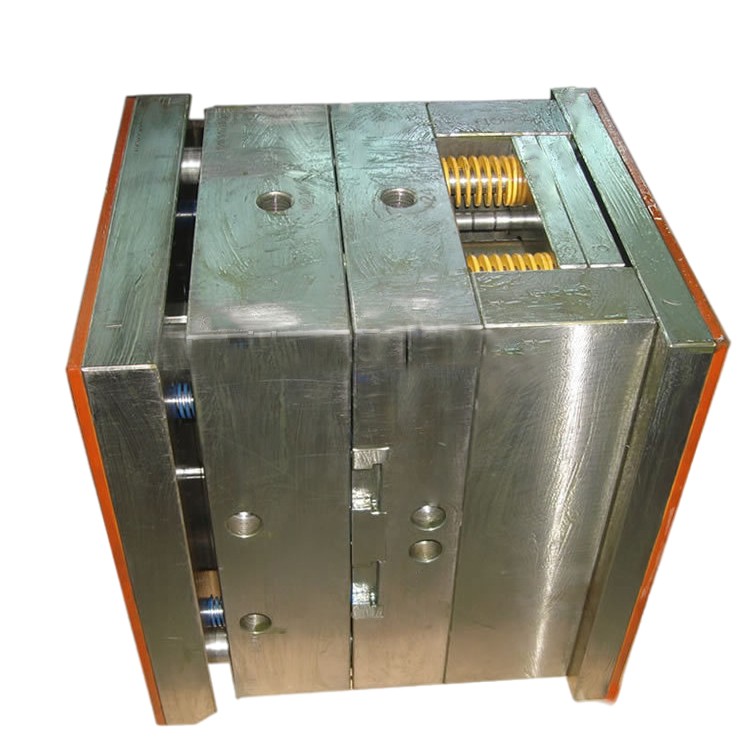

Plastic Injection Mould

Injection molds are widely used in consumer electronics, auto parts, toys, daily necessities, medical devices and other industries, providing efficient and high-quality plastic product production solutions for these industries. Through continuous technological innovation and process improvement, KCN plastic molding is gradually developing towards intelligent and automated injection molds, providing strong support for the development of modern manufacturing.

-

Cold Hot Runner Precision Plastic Injection Mould

Advance Service before sales

Email Details

1. We can provide comprehensive and professional Suggestions on equipment selection.

2. Energy consumption calculation and investment income analysis can be provided.

3. Provide tailor-made CAD drawings of workshop layout and product optimization suggestions

Advantages of tech teams

1.More than 800 sets per year mold making enable us to have rich experience across kinds of industries.

2. Enough and advance equipments for customer product characteristics.

3. Engineers can study abroad or participate in technical function training of the industry to master the latest information and technical trends of the industry.

Advantages of after-sales team

1. Lifetime free service for the machine.

2. Quick response all day long.

3. Set up domestic service team and international service team.

4. Technicians also master the debugging and maintenance of auxiliary equipment. -

Hot

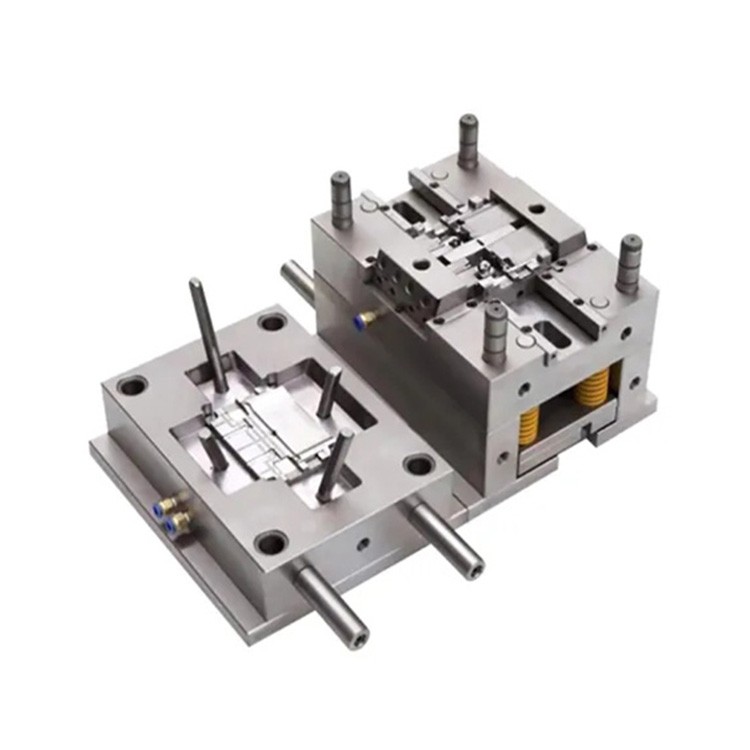

Injection Mould Auto Connector Plastic Parts Mold

Professional experience in one-stop solution on tooling and production;

Email Details

Satisfy the precision mold requirement in wide rage industry;

Can do from mold design to manufacturing.

1. Fast Quote: Based on 2D or 3D drawing, your sample, even your idea;

2. Mold Design

3. Tooling Maker: Injection mold, stamping die & die casting as well;

4. Plastic Injection Products Production

5. Secondary Process: Offer mold design, mold tooling, injection production, screen printing, spray paint and assembly one-stop service;

6.After Service: For your smoothly running machine or product use. -

Hot

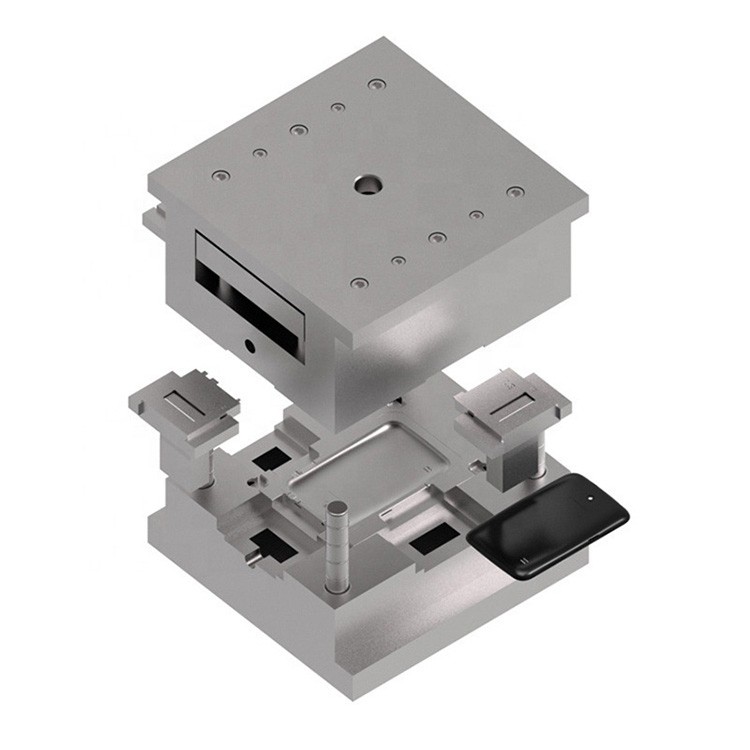

Plastic Mould For Mobile Phone Injection Cover

1. Fast Quote:

Email Details

Based on 2D or 3D drawing, your sample, even your idea;

2. Mold Design:

With more than 10 engineers, for mold design, programming, project managers, we are using CAD/CAE/CAM software to do the design, analysis & programming, to guarantee the satisfaction of customer;

3. Tooling Maker:

Injection mold, stamping die & die casting as well and provide high-volume injection molding solutions;;

4. Plastic Injection Products Production:

Our machines produce the unit parts from 1 gram to 6000 grams weight. Our machines can produce the maximum size of unit plastic part: 1.5*1.5*1.5 meters.

5. Secondary Process:

Provide mold design, mold tooling, injection production, screen printing, spray paint and assembly one-stop service;

6. After Service:

For your smoothly running machine or product use. -

Hot

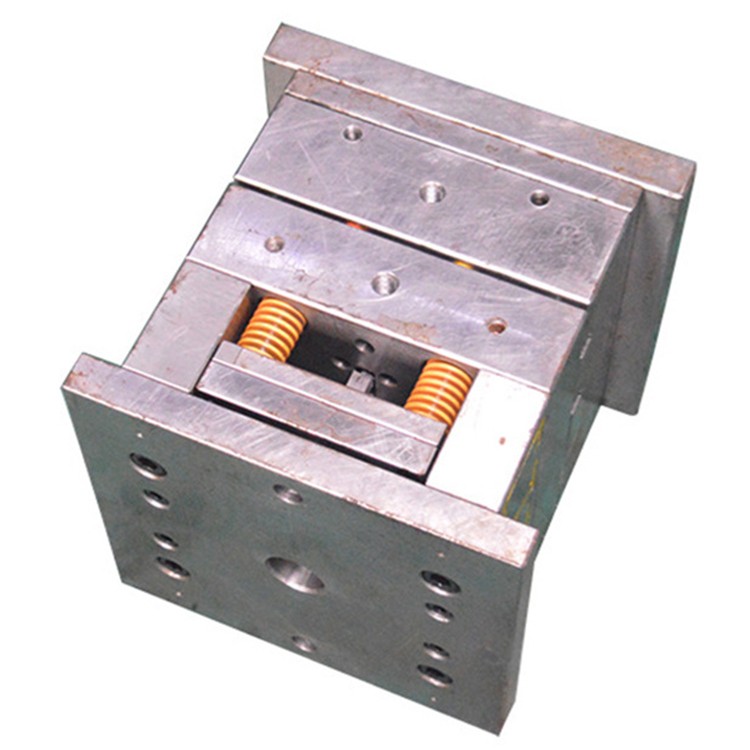

Injection Plastic Parts Mould For Industrial

One-stop Service:

Support plastic injection mold design and making service, plastic injection service, assembly work service, pad printing service, silk screen print service, paint service, ultrasonic welding service and packaging services;

Rich Experience:

High Quality, Competitive Price and Fast Delivery Time

more than 15years experience for plastic injection mould and plastic injection and developing capability;

Advance Equipment:

Imported sophisticated production and testing equipment with high stability.Injection Plastic Parts Mould Plastic Parts Mould for Industrial Injection Plastic Mould for IndustrialEmail Details -

Hot

Auto Plastic Parts Molds

Product Process:

Email Details

1. Mold Design Control

2. Mold Steel Hardness Inspection

3. Mold Electrodes Inspection

4. Mold Core and Cavity Steel Dimension Inspection

5. Mold Pre-Assembly Inspection

6. Mold Trial Report and Samples Inspection

7. Pre-Shipment Final Inspection

8. Export Product Package Inspection -

Hot

ABS Plastic Injection Mould

1. Good mechanical and thermal properties, high hardness, easy to plate metal on the surface.

Email Details

2. Fatigue resistance and stress cracking resistance, high impact strength.

3. Resistant to chemical corrosion such as acid and alkali.

4. Low price.

5. Easy to process and modify.

6. Application classification of ABS plastics: general structural parts, machine covers, covers, instrument cases, hand drill cases, fan impellers, radio, telephone and TV cases, some electrical parts, auto parts, machinery and conventional weapon parts. -

Hot

Plastic Handle Mold

1.Start from part design analysis;

Email Details

2.Mold design drawing and DFM report available so you can see how is the mold going to be before mold making;

3.If product is complex,moldflow report will be present as well;

4.In house mold making shop ensure you mold quality under well control;

5.Normally it takes 20-40 days to make mold,precise time depends on part design;

6.Can provide one-stop service for plastic product customizing works. We provide mold design, precision plastic mold making, custom best quality plastic injection molding, Assembly Work, Pad Printing, Silk Screen Print, Paint, Ultrasonic Welding and Packaging Services. -

Bathroom Parts Plastic Injection Moulding

1. Have experience for mould

Email Details

2. 3D Drawing service from plastic to plastic injection moulding tool design

3. 2 special after sales team to help you solve any problem for plastic injection mold tooling and parts.

4. We are ready to sign a contract with you in case you need to ensure our quality OR delivery date of our plastic moulding tooling and plastic parts.

5. We have professional plastic injection mold tooling designer and plastic part producing line.

6. Plastic Injection Mould OEM & ODM Services -

Fitness Equipment Plastic Mold For Injection Spare Part

We can offer the full range of service from mold designing, making, plastic part molding to printing, assembly, package, and shipping arrangement.

Email Details

1. In the service of plastic injection, Ideal plastic is more than just an injection molder.

2. We provide solutions to manufacturing from start to finish.

3. Our expertise enables us to provide clients with superior product by providing the highest quality in design, development, and solutions for precision injection molding and related manufacturing.

4. We have over 15 years production experience.

5. Have more than 50 plastic injection mold machines, variety of precision mold produce equipment and spray printing equipment and more than 7500 square meters workshop.