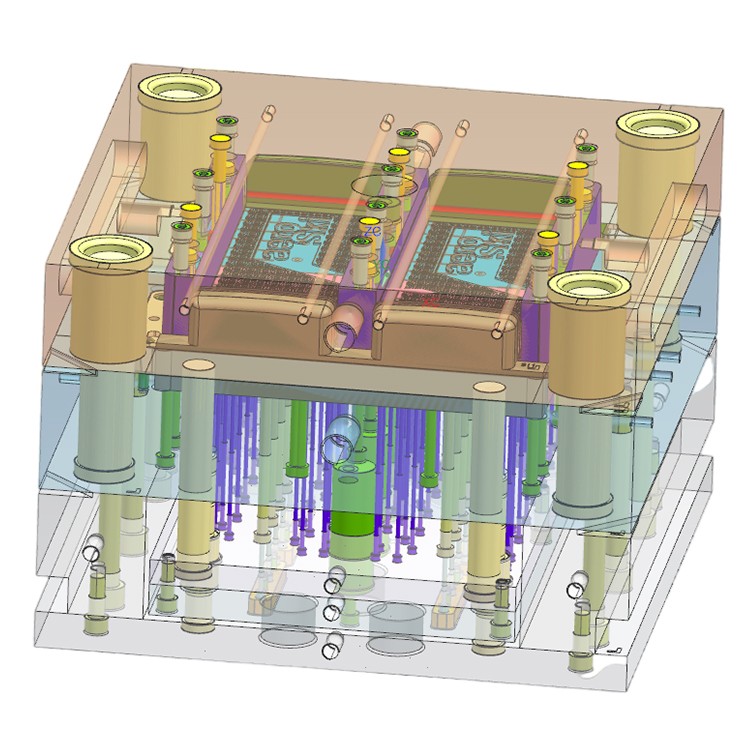

Plastic Fitness Equipment Mould

-

Fitness Equipment Spare Parts Plastic Injection Mold

1. Start from part design analysis;

Email Details

2. Mold design drawing and DFM report available so you can see how is the mold going to be before mold making;

3. If product is complex, moldflow report will be present as well;

4. In house mold making shop ensure you mold quality under well control;

5. Normally it takes 20-40 days to make mold, precise time depends on part design;

6. We can provide mold design, mold tooling, injection production, screen printing, spray paint and assembly one-stop service;

7. With more than 50 injection molding machines, plastic extruding machines, as well as various accurate mould opening equipment, lacquer spraying and printing equipment;

8. Our machines produce the unit parts from 1 gram to 6000 grams weight. Our machines can produce the maximum size of unit plastic part: 1.5*1.5*1.5 meters. -

Plastic Fitness Equipment Injection Parts Mould

1. We have more than 50 plastic injection mold machines、variety of precision mold produce equipment and spray printing equipment.

2. Our workshop area is about 7500 square meters;

3. We can provide ONE-STOP SERVICE for plastic product customizing works. We provide mold design, precision plastic mold making, custom best quality plastic injection molding, Assembly Work, Pad Printing, Silk Screen Print, Paint, Ultrasonic Welding and Packaging Services.

4. ISO 9001 Certified for all of our plastic injection tooling and plastic mould part, injection mould and our factory;Plastic Fitness Equipment Mould Plastic Fitness Equipment Injection Mould Plastic Injection Parts MouldEmail Details -

Fitness Equipment Plastic Cover Injection Mould

1. Provides service of part design, prototype making, mold design, mold production, mass production and assembly service in house. We are cooperating with many clients all over the world and have a deep understanding of the mold industry, our experience range from simple design to challenging technical parts;

Email Details

2. Our service also covers in making CNC prototypes, die casting, injection mold with production; And sandblasting, painting, anodizing, electroplating, high polishing and laser etching also can be finished well.