What is an injection mold

What is an injection mold

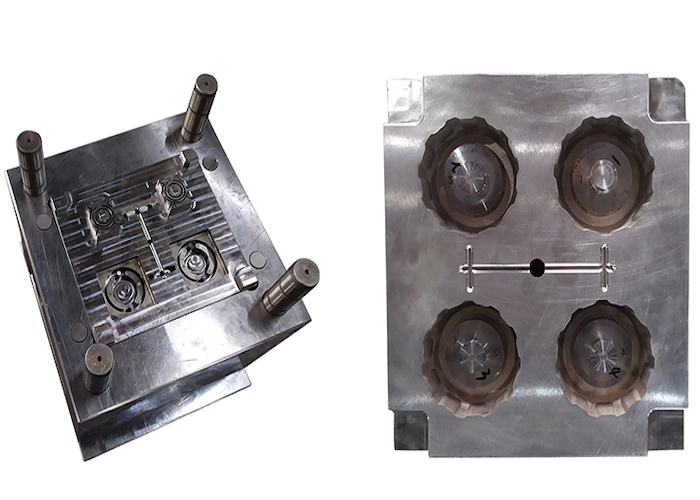

Mold injection molding is a processing method used in the mass production of certain complex-shaped parts. The specific principle refers to: the heated and melted plastic raw material is pushed by the screw of the injection molding machine into the cavity of the plastic mold under high pressure, and after cooling and solidifying, the plastic molding product is obtained.

The plastic mold consists of a moving mold and a fixed mold. The moving mold is installed on the movable template of the injection molding machine, and the fixed mold is installed on the fixed template of the injection molding machine. During injection molding, the movable mold and the fixed mold are closed to form the gating system and the cavity, and the movable mold and the fixed mold are separated to take out the plastic product when the mold is opened.

Although the structure of the mold may vary due to the variety and performance of the plastic, the shape and structure of the plastic product, and the type of the injection machine, the basic structure is the same. The mold is mainly composed of pouring system, temperature adjustment system, molding parts and structural parts. Among them, the pouring system and molding parts are the parts that are in direct contact with the plastic and change with the plastic and the product. They are the most complex and the most changing parts in the mold, requiring the highest processing finish and precision.

Injection mold is a tool for producing plastic products; it is also a tool for giving plastic products complete structure and precise dimensions. Injection molding is a processing method used in the mass production of certain complex-shaped parts. Specifically, it refers to injecting the heated and melted plastic into the mold cavity under high pressure from the injection molding machine, and after cooling and solidifying, a molded product is obtained.